A manufacturing process that combines the amazing properties of one material with the powerful benefits of another to form a fine fiber could find innovative uses in industry, textiles and even medicine.

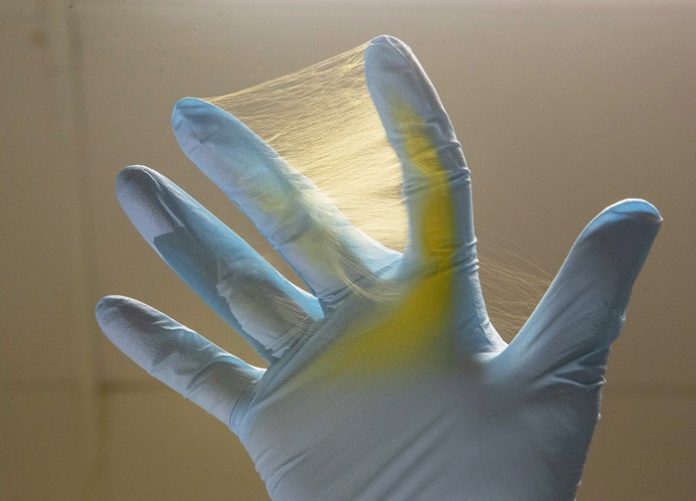

Called Electrospinning, it involves two or more liquid polymers being pumped into a nozzle that produces drops, which turns into a superfine jet when an electric voltage is applied to it. The new product is composed of a core of one material surrounded by a sheath of another. It appears deceptively simple but the chemistry of the final product is what makes it so versatile, as it combines polymers with properties that you do not normally find in nature.

The large surface area and custom properties of the fibers make them an ideal drug-delivery system. Patients who have to take drugs multiple times per day for conditions such as Parkinson’s disease might be able to take a single long-acting dose made from electrospun medicines. Electrospun medicines with fibers that only dissolve at a particular acidity in the digestive system can be made to delay or extend the release of the active ingredients.

Researchers could also put drug molecules on the inside for a treatment surrounded by pain-relief molecules on the outside. The electrospun fiber would also be used as a tampon-like application to trap and kill sperm, or it could release anti-infective drugs to prevent sexually transmitted diseases. Other innovative uses for electrospun fibers in the medical field are only being discovered.